INCONCRETO NEWS

Powering the Future: The Rise and Current State of Electric Vehicle Batteries

The Rise of Electric Vehicle Batteries and their Implications for the Automotive Industry and Global Energy Economy

Electric vehicle (EV) batteries are the power source that allows electric vehicles to run. These rechargeable batteries store the electrical energy necessary to power the vehicle’s electric motor. Lithium-ion batteries are the most common type of battery used in EVs because of their high energy density, long lifespan, and low self-discharge rate.

Lithium-ion batteries work by moving lithium ions from the negative electrode (anode) to the positive electrode (cathode) while charging, and vice versa while discharging. This movement of ions generates an electrical current that powers the electric motor. The batteries are charged by plugging the vehicle to an electric charging station or by using regenerative braking, which converts the kinetic energy of the moving vehicle into electrical energy to recharge the battery.

As concerns about climate change and air pollution have increased, the demand for EVs has risen, and as a result, EV battery usage has become more widespread. In 2020, EV sales increased by 43%, and despite the COVID pandemic, 6.6 million EVs were sold in 2021, doubling the previous year’s amount, and setting a record in EV sales history. EVs accounted for nearly 10% of global car sales in 2021, representing 1.4% of all cars on the world’s roads, for a total of almost 16.5 million EVs sold worldwide.

In 2022, sales of electric cars increased by 55%, with over 10 million electric cars sold worldwide, primarily in China, Europe, and the United States. The demand for electric cars is booming, with sales expected to leap 35% this year, following a record-breaking 2022. As a result, EVs’ share of the overall car market has surged from around 4% in 2020 to 14% in 2022 and is projected to rise further to 18% this year, according to the latest International Energy Agency (IEA) projections. At least 30 million zero-emission electric vehicles are expected to be on EU roads by 2030, and it is projected that up to 30% of all new vehicles sold will be electric by 2030.

“Electric vehicles are one of the driving forces in the new global energy economy that is rapidly emerging – and they are bringing about a historic transformation of the car manufacturing industry worldwide,” stated IEA Executive Director Fatih Birol. “The trends we are witnessing have significant implications for global oil demand. The internal combustion engine has gone unrivalled for over a century, but electric vehicles are changing the status quo. By 2030, they will avoid the need for at least 5 million barrels a day of oil. Cars are just the first wave: electric buses and trucks will follow soon.”

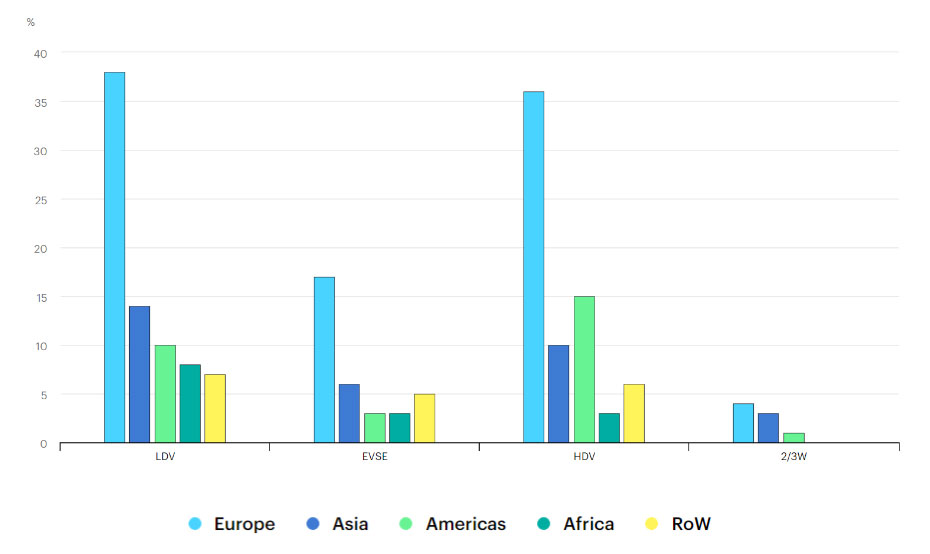

Share of global electric car markets by selected carmakers, 2022

Notes: Appears in Global EV Outlook 2023

LDV = light-duty vehicle; HDV = heavy-duty vehicle; 2/3W = two/three-wheeler; EVSE = electric vehicle supply equipment; RoW = rest of the world. Countries are counted when they have at least one EV-supportive policy in a given category, for example a purchase incentive, a national target for sales shares, or favourable taxation. Coverage of EVSE-related policies is based on LDV and HDV sales

Battery Blues: The Environmental Cost of Electric Vehicles

With their efficient motors and lack of tailpipe emissions, EVs are seen as a perfect instrument for climate-positive mobility. However, despite their benefits, there is still one major issue that needs to be addressed: the CO2 emissions generated by the production and disposal of EV batteries.

To address this issue, researchers and manufacturers are working to develop more sustainable battery production methods, including using recycled materials and reducing the amount of energy required in the manufacturing process. There is also a push to improve the recycling and reuse of EV batteries to reduce waste and further lower emissions.

According to the Massachusetts Institute of Technology’s (MIT) insights into Future Mobility study, on average, gasoline cars emit more than 350 grams of CO2 per mile driven over their lifetimes. Hybrid and plug-in hybrid versions scored at around 260 grams per mile of carbon dioxide, while the fully battery-electric vehicle created just 200 grams. The study also found that if EVs had a shorter lifespan than gas cars, they would still remain 15% better than a hybrid and far better than a gas car.

As more countries add more clean energy to their mix, EVs are expected to become even greener. MIT’s report predicts that gasoline cars will drop to around 225 grams by the year 2050, while battery EVs could drop to around 125 grams, and perhaps even down to 50 grams if the price of renewable energy were to drop significantly.

“We shouldn’t claim victory that with this switch to electric cars, problem solved, we are going to have zero emissions,” says Sergey Paltsev, Deputy Director of the MIT Joint Program on the Science and Policy of Global Change, “No, that’s not the case. But electric cars are actually much, much better in terms of the impact on the climate in comparison to internal combustion vehicles. And in time, that comparative advantage of electric cars is going to grow.” Despite the challenges associated with EV battery production and disposal, the benefits of EVs far outweigh the negative impacts.

Revealing the carbon footprint of EV batteries

A carbon footprint of an EV battery includes the greenhouse gas emissions produced during the entire lifecycle of the product, from mining raw materials such as lithium, cobalt, and nickel, to the manufacturing process and transportation of the battery to the vehicle assembly plant. These raw materials are often mined in countries with lax environmental regulations and the mining process can be energy-intensive, leading to the release of toxic chemicals and heavy metals that can harm both humans and wildlife.

Although EVs are clean, their batteries have a high carbon footprint. To deal with it, leading manufacturers are exploring alternative materials, such as solid-state batteries, that require fewer raw materials and are less energy-intensive to manufacture. Companies are also looking for ways to recycle materials used in EV batteries to reduce the need for new mining operations and lower emissions during manufacturing.

More than 100 original equipment manufacturers (OEMs) and their suppliers in the auto industry have committed to reducing emissions through the Science Based Targets initiative, with more expected to join. The carbon footprints of EV battery production vary significantly among different OEMs due to factors such as vehicle type, range, freight specifications, production, and sourcing locations, and design choices, particularly the energy sources employed in manufacturing various battery components.

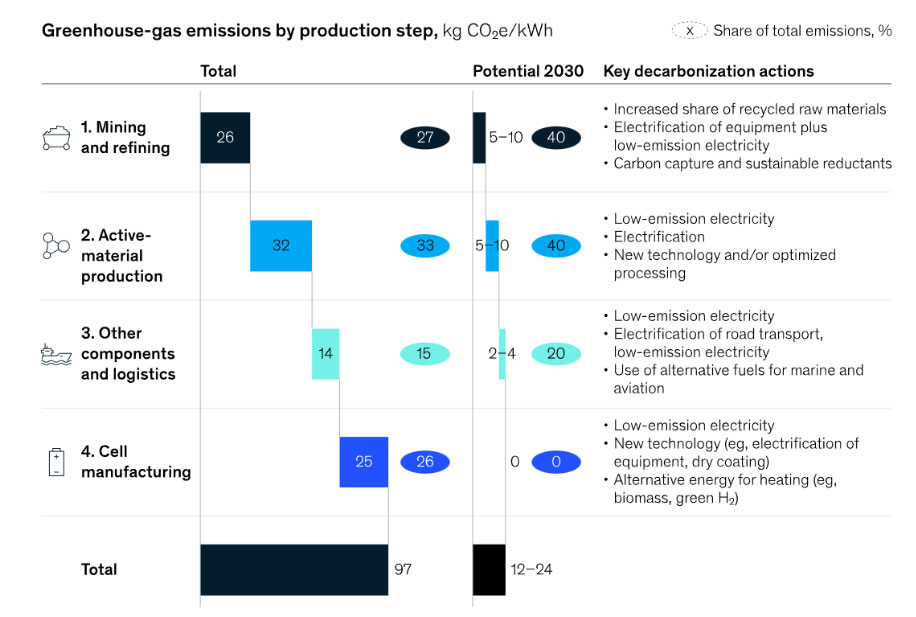

According to McKinsey & Company report on “The race to decarbonize electric-vehicle batteries” from February 2023, significant reductions in carbon emissions from EV battery production are possible in the next five to ten years.

Today battery makers’ focus should be on reducing emissions in four key areas

Note: Figures may not sum to 100%, because of rounding.

Source: Greenhouse gases, Regulated Emissions, and Energy use in Technologies (GREET); MineSpans by McKinsey; McKinsey Battery Insights

McKinsey & Company

Driving Toward Sustainability: Global Targets for Reducing EV Battery Emissions

Several countries and regions have set ambitious targets for reducing the emissions associated with EV batteries. Here is an overview of the main goals established all over the world and the different approaches taken by Europe, the USA, and China.

Europe has set a target of reducing the carbon footprint of EV batteries by 80% by 2030, including the production, life cycle, recycling, and disposal. Global demand for batteries is set to increase 14-fold by 2030 and the EU could account for 17% of that demand. To achieve this goal, the European Union has launched several initiatives aimed at optimizing the value chain of EV batteries, including the development of a sustainable battery ecosystem with sustainable mining, circular design, and responsible sourcing of materials.

The USA has taken a different approach to reducing the emissions associated with EV batteries. The US Department of Energy (DOE) has set a goal of reducing the cost of EV batteries to $100 per kilowatt-hour by 2025. This cost reduction would be achieved through technological advancements, improved manufacturing processes, and economies of scale. Transitioning to a light-duty fleet of HEVs and PEVs could reduce U.S. foreign oil dependence by 30-60% and greenhouse gas emissions by 30-45%, depending on the exact mix of technologies.

China, the world’s largest market for EVs, has set a target of achieving a 50% reduction in the carbon footprint of EV batteries by 2025. The Chinese government has implemented policies, including financial incentives for the development and production of high-performance batteries, and the promotion of EVs in public transportation.

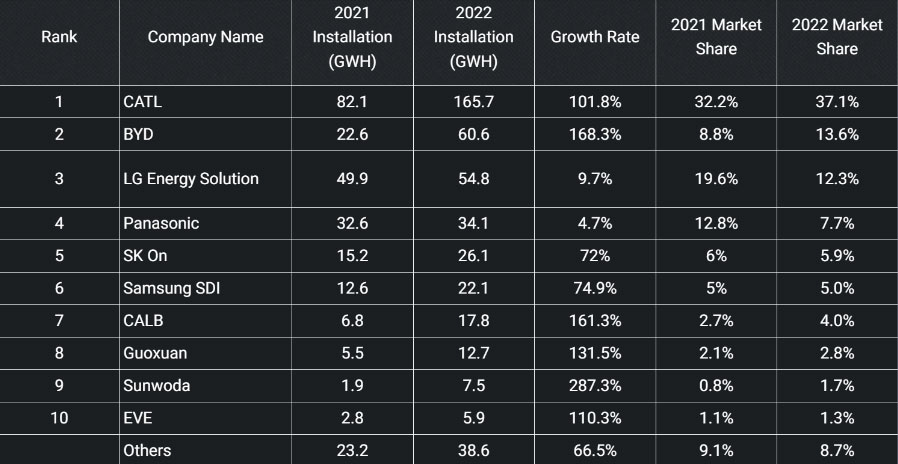

Chinese battery manufacturers have exerted their dominance over the global supply of electrical vehicle batteries, with six out of the top ten companies being Chinese, led by Contemporary Amperex Technology (CATL), with an impressive 37.1% share of the market based on the latest report from SNE Research published in January 2023. CATL supplies EV batteries to automakers giants including Tesla, Honda, Volkswagen, Volvo, BMW, Dongfeng Motor, and SAIC Motor.

Europe, the USA, and China have all set ambitious targets for achieving this goal, each with its unique approach. Optimizing the value chain of EV batteries is crucial to achieving these goals and creating a truly sustainable mobility system. By working together, the global community can reduce the environmental impact of EV batteries and ensure a more sustainable future.

Electric vehicle battery market share of the top ten companies 2021-2022

Source: SNE Research

INCONCRETO, as an international consultancy, can provide expertise in capital project optimization in the energy sector.

Connect with our team!

We combine technical expertise with large program execution practices, improving predictable outcomes and steering profitability on Capex/Opex project investments.

For further readings, you may consult these sources:

Explore the IEA April’s Global 2023 report: https://www.iea.org/reports/global-ev-outlook-2023

https://statzon.com/insights/e-mobility-europe-an-overview-of-europes-latest-electric-vehicles-data

https://climate.mit.edu/ask-mit/are-electric-vehicles-definitely-better-climate-gas-powered-cars

Newsletter

© INCONCRETO. All rights reserved. Powered by AYM